Rules for Preparing Decoctions and Some Environmentally Friendly Plant Protection Products

Author(s): доц. д-р Желю Аврамов, Лесотехнически университет, София

Date: 12.01.2026

1065

By using the process known as the “Systemic Acquired Resistance” (SAR, SDH) in plants and its principles of action in environmentally friendly vegetable production, alongside the widely recognized copper- and sulfur-based products, various decoctions are also used. These products have different sources for preparation, because their content of substances (glycosides, alkaloids, essential oils and phytoncides) in plants varies and is influenced by the phenophase of development and by the growing conditions.

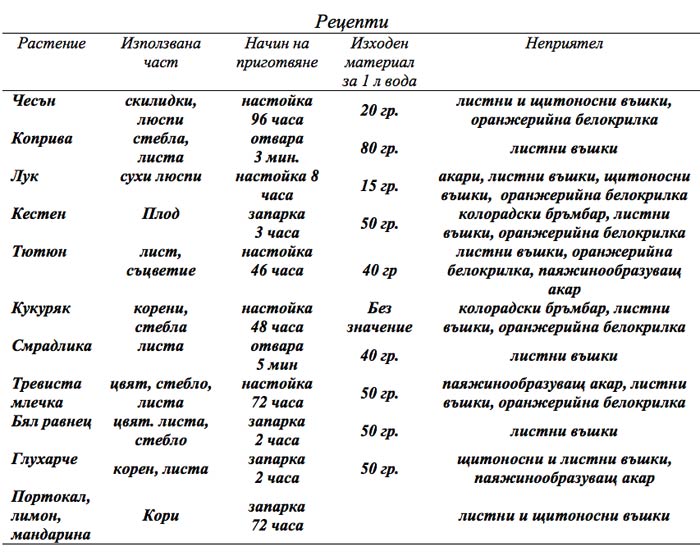

The effectiveness of all alternative methods for pest control in urban agriculture depends on correctly implemented recipes and proper application (treatment).

Nettle decoction acts against aphids

The raw materials for future decoctions are collected from different plant organs and during a precisely defined period of their vegetation, such as:

- leaves, which are collected before and during flowering of the species;

- flowers – at the beginning of flowering;

- roots – in early spring or in autumn;

- fruits – collected during ripening.

The effect is obtained after several treatments. The ready-to-use spray solutions must not be stored. Three methods of preparation are distinguished, bearing respectively the names decoction, infusion and macerate.

The decoction is prepared by boiling the previously collected plant-based raw material for 3–5 minutes in a closed vessel. Then it must steep for a certain period from 1 to 12 hours. During this period, the solution must be homogenized and, before use, filtered through a strainer containing cotton.

Sumac decoction

The infusion is prepared by pouring hot water over the collected plant material. It must stand for at least one hour, after which it is strained and left to cool for future use.

The macerate is prepared by soaking in cold water in a closed vessel. The obtained concentrates are stored in a cool and dark place. Homogenization is recommended.

Before use, all solutions, in order to become working solutions and to avoid the manifestation of phytotoxicity in the treated plants, should preferably be diluted with water in a ratio of 1:1, and it is also necessary to add 5 millilitres of liquid soap per litre of working solution. This solution has only contact action and therefore precise spraying is required – 2–3 times at 7–8 day intervals. It should be noted that the extracts act even on insects that have developed resistance to synthetic plant protection products.

Thanks to this method, the benefit is twofold:

- the environment is not polluted;

- the yield is ecologically clean.

Rules for preparing Bordeaux mixture

Bordeaux mixture is a colloidal suspension with particle diameter from 3 to 4 microns, with very good adhesiveness, unsatisfactory wetting capacity and good floatability. When left to stand for a longer time, its particles settle; therefore, before each use it must be well homogenized and strained. Its stability and application period are up to 24 hours.

The fastest way to prepare this mixture is by weight, using already weighed products. To obtain 10 litres of 1% Bordeaux mixture, proceed as follows: in a non-metallic container with 9 litres of water, dissolve 100 g of copper sulfate. In a second container, dissolve 100–150 g of hydrated lime and dilute in one litre of water to obtain lime milk. Usually the lime milk is poured in a thin stream into the diluted solution of copper sulfate with continuous stirring. When these quantities of lime are added, a solution with pH 8–8.3 is obtained. Recently, ready-made concentrated Bordeaux mixtures have become increasingly popular; they are easy to prepare and use, but only when the manufacturers’ requirements are strictly observed and the expiry dates are taken into account (Agriflor Ltd.; Burall Ltd. and others).

Bordeaux mixture kills zoospores, germinating spores of most fungi and some bacteria; therefore spraying with it must be carried out before the plants have become infected, i.e. as preventive treatment. With copper-containing solutions, it is possible to provide effective protection of plants against downy mildews, smuts and rusts, but they are not effective against powdery mildews and are not applied to cucurbit crops. Copper-containing solutions have a bactericidal effect and are therefore used to control angular leaf spot in cucumbers, bacterial blight in walnut, black rot in sesame, bacterial diseases in beans and others. Copper compounds exhibit phytotoxicity to peaches, apricots, cucurbits, gooseberries, some apple, pear and plum cultivars.

It is used for winter spraying of fruit trees at a concentration of 1–2%, and for spring and summer spraying (on green leaf mass) at 0.5–1%. For grapevine, the best concentration is 1%. According to some researchers (Novoa et al., 1996), the last two treatments at a concentration of 1.5% suppress the formation of mycelium of grey mould and partially of powdery mildew. It is also effective against Phomopsis cane and leaf spot (escoriose) and anthracnose in grapevine at the same concentration in the appropriate phenophase.

In vegetable crops such as tomato and potato, it is applied against late blight, “elk eye” (Phytophthora infestans symptoms), bacterial diseases and against Alternaria at a concentration of 0.5 to 1%, avoiding the flowering phase.

Rules for preparing lime-sulfur solution

Sulfur has been used as a fungicide, insecto-acaricide and fertilizer for almost 200 years. It was first applied in 1821 as a disinfectant for wine vessels against mould. Later, in 1840, experiments were carried out in England to treat vineyards against powdery mildew. Only in 1855 did Henri Becquerel, after purification and refining, manage to obtain sulfur of high purity and successfully use it to control powdery mildew in grapevine.

To prepare 10 litres of the solution, 2.4 kg of sulfur powder and 2.4 kg of quicklime are needed. In an iron vessel with a capacity of 10 to 15 litres, the quantity of quicklime is added with 3 to 4 litres of water. The iron vessel is placed on a hearth and, over low heat, the mixture is homogenized until a thick lime milk is obtained.

To this mixture, while constantly stirring, sulfur is added in portions so that the mixture acquires the consistency of a thick slurry. Usually, during the heating process a certain amount of water is lost and continuous topping up is necessary, and after adding the sulfur to the lime milk, water is added until the final volume of 10 litres is reached. An important condition for proper implementation of the recipe is to ensure that the volume does not fall below 10 litres.

The fire is intensified and boiling must continue for 30–40 minutes.

During this time the solution darkens and changes from orange-red to green-black and the sulfur scum disappears.

The obtained solution is left to cool and clarify. On the following day only the clear solution is separated and the sediment is discarded.

Lime-sulfur solution is a transparent liquid with an orange-red colour and a hydrogen sulfide odour. When stored in glass containers, plastic barrels or covered with mineral oil, it can be preserved for a long time, provided that it does not freeze in winter.

Lime-sulfur solution cannot be combined with Bordeaux mixture.

It is applied for winter treatment of pome fruit and some stone fruit species when diluted with water in a ratio of 1:6, and for sensitive stone fruits and vineyards – 1:10. During the vegetation period it is used in a ratio of 1:50 to 1:100. For spraying apples, pears, quinces and plums, it is recommended to apply it before flowering at a concentration of 2% and during and after flowering at 1.6 to 1.8% (Hristov, 1969).

Sulfur-containing products are effective against the causal agents of powdery mildews, most ascomycete and mould fungi and rusts, but they do not affect downy mildews. Recent studies show that, in addition to preventive and contact action on phytopathogens, sulfur also exhibits curative action against powdery mildew in grapevine, blocking the spores and mycelium of the fungus up to the 5th day after treatment (Decoin, 1999).

Rules for spraying plants

Sometimes plants are infected by various diseases and pests that must be controlled in order not to lose them. For controlling harmful insects, products are used that are distributed with sprayers. The wide range that you can find in specialized stores will help you choose the one most suitable for your garden. It must also be convenient for you, because you will carry it while spraying the plants. The quantity of product and the quality of treatment are very important.

The success of a treatment operation is determined by compliance with the following rules when spraying plants:

1. During treatment it is necessary to use work clothing and personal protective equipment, in accordance with the requirements of European legislation (Dir 89/656/EEC and 89/391/EEC, Dir (EU) 2019/1832) on the minimum health and safety requirements for the use of personal protective equipment by workers:

a) chemical-resistant gloves;

b) work suit;

c) work shoes;

d) work cap;

e) protective goggles;

f) respirator mask, and after treatment, these single-use items must be disposed of at appropriate designated locations.

2. Before treatment, the external condition of the sprayer must be inspected, the nozzle must be checked to ensure it is clean and, if necessary, washed with clean water.

3. The droplet size formed by the nozzles used must be determined. For this purpose, white sheets of paper are placed on a random plant at its different ends and a test spraying with water is performed. If necessary, the distances of the nozzle openings are adjusted and only then is the preparation of the working solutions started.

4. The working solution must be prepared in quantities that can be used on the same day.

5. Working solutions must be prepared in the following sequence: In a small container, the quantity of product (decoction, infusion or macerate or another) is added and diluted with water. To this solution, with stirring, the required amount of liquid soap or other detergent is added (per litre of working solution in the sprayer = 0.5 ml). A small amount of water is added to the bottom of the sprayer (up to 1/10 of the total volume of the working solution) and the solution from the small container is poured in a thin stream with continuous stirring. The container is rinsed several times and the remaining quantity of water is added. Emulsion solutions must in no case form an oil film on their surface.

6. In winter, when combating overwintering pest stages, defoliated trees are sprayed abundantly with working solution in large droplets. The aim is to obtain complete wetting of the entire plant.

7. During the vegetation period, spraying is carried out with small quantities of solution and with the smallest possible droplets. When using products with contact action, the fullest possible coverage of the upper and lower leaf surfaces must be achieved (this is particularly necessary for fungicides, acaricides and herbicides), whereas when working with products that have penetrating and especially systemic action, this is not necessary.

8. When applying plant protection products (PPP), the dose of the product must be strictly observed (for example, herbicides are dosed per decare). Therefore, overlapping of strips that have already been sprayed during the first pass of the sprayer must not be allowed. On overlapped areas, twice the amount of product accumulates and undesirable phytotoxic effects may occur there during the current or following years. (This is the reason why instructions for herbicides are given in grams per decare and not in percentage of working solution).

9. Spraying must be done at wind speeds up to 3 m per second, and the operator must always remain with his back to the wind.

10. The instructions for use written on each product label must always be read and the concentrations and time of application (growth stages of the plants and types of pests) must be strictly followed.

11. In spring and summer, spraying is done until 9–10 a.m. and after 8 p.m., in order to avoid burns (they can occur even when spraying with clean water) if spraying is done during the hot hours. At temperatures above 20 °C, treatments are stopped (in summer, night treatments after 10 p.m. are applied).

12. During treatment, smoking and food consumption are not recommended.

13. After completion of treatment, the tank of the sprayer, hoses and nozzles are rinsed three times.

References

1. COUNCIL DIRECTIVE (89 / 656 /EEC of 30 November 1989) on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace (third individual directive within the meaning of Article 16 ( 1 ) of Directive 89/ 391 /EEC)

2. COMMISSION DIRECTIVE 2019/1832 (EU) of 24 October 2019 amending Annexes I, II and III to Council Directive 89/656/EEC as regards purely technical adjustments.

3. Nikolov A., 2017. Phytopharmacy, ISBN: 978-954-8319-71-3.

4. Stancheva Y., 2004. General plant pathology, ISBN: 954-6422-14-2.

5. Grainge M., Ahmed S., 1987. Hand book of plant with pest control.

6. Regnault-Roger C., Philogene B. J. R., Vincent C, 2008. Biopesticides d’origine vegetale, p. 245.

7. Ross A.F., 1961. Systemic acquired resistance induced by localized virus infections in plants, Virology 14(3):340-358, DOI:10.1016/0042-6822(61)90319-1.

8. Bhawsar S., 2014. Induced Systemic and Systemic Acquired Resistance, https://www.biotecharticles.com/Agriculture-Article/InducedSystemic-and-Systemic-Acquired-Resistance-3227.html.

9. Ingham J. L., 1973. Diseases Resistance in Higher Plants The Concept of Per-infectional and Post-infectional Resistance, Journal of Phytopathology, Vol 78(4), 314-335.

10. Ahuja I., Kissen R., Bones A. M., 2012. Phytoalexins in defence against pathogens. Trends Plant Sci, 17, 73-90, doi: 10.1016/j.tplants.2011.11.002.

11. Benhamou N., 2009. La résistance chez les plantes. Principes de la stratégie défensive et applications agronomiques. Éditions TEC & DOC - Lavoisier, Paris. 376 p.

12. Martinez J. A., 2012. Nature Fungicides Obtained from Plants, p. 3-28, InTech-Natural_fungicides_obtained_from_plants.pdf

13. Novoa D., Payan J. J., Steva H., Goebet O., Vergnet, 1996. Effect Secondaires de la Bouille Bordolaise sur L’oidium de la vigne, Phytoma, 487, 41-44.

14. Hristov A., 1969. Phytopathology, Edi Zemizdat.

15. Decoin M., 1999. Vine et cereals, les vertus de soufre. Phytoma, 514, 4.

![MultipartFile resource [file_data]](/assets/img/articles/заглавна-отвари-пръскачка.jpg)